Imagine building an underwater robot at camp. That’s what pre-engineering students at Grand Haven High School (GHHS) did over the summer with the help of Shape Corp., a Grand Haven (Mich.) manufacturing company that is in its second full year of partnering with GHHS in the SME Education Foundation PRIME (Partnership Response In Manufacturing Education) program.

Imagine building an underwater robot at camp. That’s what pre-engineering students at Grand Haven High School (GHHS) did over the summer with the help of Shape Corp., a Grand Haven (Mich.) manufacturing company that is in its second full year of partnering with GHHS in the SME Education Foundation PRIME (Partnership Response In Manufacturing Education) program.

“I wanted to come up with an interesting, engaging activity that would be challenging to kids,” said Jeremy Case, technical education teacher at GHHS, which is located in a beach town on the eastern shore of Lake Michigan. “I wanted them to be able to create something, and walk through the critical thinking and problem-solving, and underwater robotics seemed to be a really cool fit. But I think the best part was, I had two gentlemen from Shape who were here every single day working with the kids.

“So as these kids were learning about this technical area, they were learning how to work in a team and move a project forward, and use the engineering design process to create a product that will compete and do a number of different things. And it was fun. It was a classic D-I-Y, underwater robotic build with PVC pipe.”

Last year, Shape Corp. provided students with a tour of its facility, and also participated in a Q&A session where students found out about the variety of jobs that are available at Shape. This school year, the company is offering second-level PRIME students the opportunity to participate in an all-day engagement activity that will team them with Shape personnel as they work through a business problem, come up with solutions, and then test those solutions on-site with Shape engineers and manufacturers.

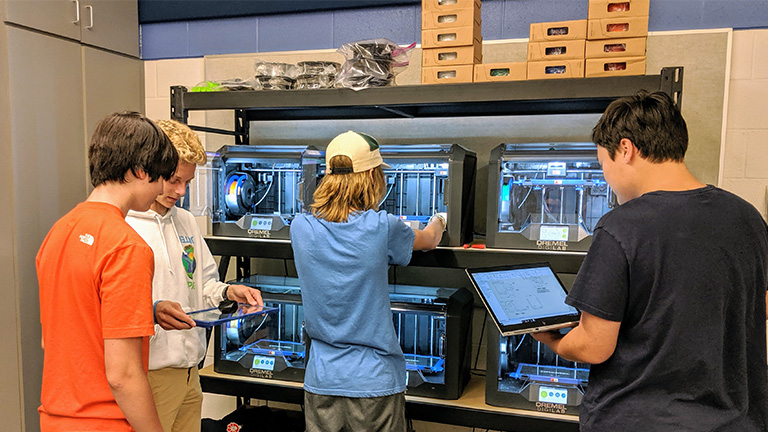

In the meantime, the GHHS PRIME program’s 40 second-level students are working on design for manufacturing (DFM) strategies, creating 3D-printed connectors to make whatever they want to make.

In the meantime, the GHHS PRIME program’s 40 second-level students are working on design for manufacturing (DFM) strategies, creating 3D-printed connectors to make whatever they want to make.

At the same time, the program’s 60 first-level students are learning about solid modeling, including what is involved in designing a part — in this case, a simple 3D-printed bag tag. “It's amazing when you see kids’ eyes light up because they're seeing their design take shape and real form, and that is so fun to see for the first time for these kids,” said Case.

Hayden Clark, a GHHS senior in pre-engineering, learned more than just technical skills from one of his class projects — an extreme redesign project that involved drawing, modeling and communicating with other students to redesign a product. “Communication is so important, especially in an engineering environment,” he said. “Engineers need to be able to express ideas that they have to other people. They also need to work together to solve the many problems people have today.”

Regarding the GHHS PRIME program, Hayden says, “I like the exposure that we get to the engineering and manufacturing environment. A lot of students, including me, didn’t actually know what an engineering career was. In these classes, we learned the processes and mentality behind engineering. We got to go through some of these processes as well.”

Hayden’s experience with PRIME has been so positive that he is looking into studying aerospace engineering at the University of Michigan, Western Michigan or Purdue. “I like the mechatronics aspect of aerospace, and I want to solve those types of problems in aeronautical and astronautical environments,” he said.

Case, the technical education teacher, said other GHHS students are also getting a wealth of experience through the PRIME program. “We have a number of 3D printers in the classroom and we have some different tools that are at our disposal, whether they be inspection tools or precision measurement tools that we use on a regular basis. Eventually, as we get into mechatronics and robotics to be able to bridge the mechanical with the electrical, it’s going to be huge."

Case, the technical education teacher, said other GHHS students are also getting a wealth of experience through the PRIME program. “We have a number of 3D printers in the classroom and we have some different tools that are at our disposal, whether they be inspection tools or precision measurement tools that we use on a regular basis. Eventually, as we get into mechatronics and robotics to be able to bridge the mechanical with the electrical, it’s going to be huge."

In addition to the current PRIME partnership with Shape Corp., Case said he sees future opportunities to partner with other local businesses. “The beauty of what we're doing here at Grand Haven High School is really this pre-engineering program that gets into design, solid modeling, additive manufacturing, design for manufacturing and critical thinking. When you look at that skill set, you can reach a large number of businesses here in town."

And the best thing is, both the students and the businesses stand to benefit — the students with eventual jobs, and the manufacturers with trained workers ready to fill those jobs.

Learn More about Shape Corp.'s partnership with Grand Haven High School